Which coupling is best for your application?

Bellow– Continuous motion, speeds up to 5k rpm, avoid e-stop and directional changes

Disc– Good for rapid Accel/Decel, stiff with parallel flexibility, ideal for servo application

Oldham– electrical isolation, mechanical fuse, angular, good with pumps

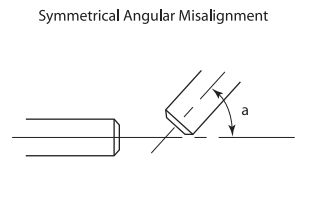

Jaw– noise isolation, large load, shaft endplay

Encoder– low inertia, electrical isolation

Design focus: Rigidity, Life, alignment

Why use a flexible shaft coupling?

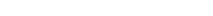

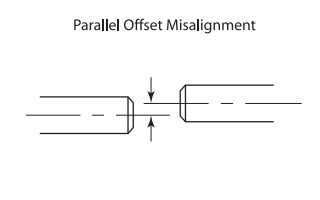

- Reduces bearing failure due to misalignment (shown below)

- Human error in assembly

- Thermal expansion will displace set positions

- Absorb shock and vibration

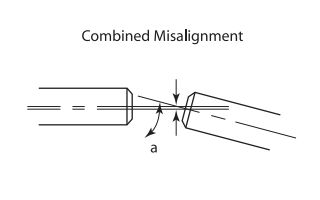

Types of Misalignment: Angular, parallel, axial or combination

- Reduces frictional heat built-up on motor shaft, encoder, pumps, etc

Rototime Coupling

Flexible shaft couplings are designed to enable easy connectivity between shafts of servomotor, stepmotor, AC/DC motor, gearbox and encoder. The couplings are designed to transmit torque and rotational angle while absorbing angular, parallel offset and shaft end-play misalignment.

Misalignments are sometimes caused not only by equipment assembly, but also by vibration, heat expansion, wear of the support bearings, etc.

Selection Calculation

Calculate Motor Torque

Motor Torque (N.m) = KW x9550/rpm

1N-m = 8.856 in-lbs

KW= motor watt

Note: Larger coupling will have larger mass and inertia.

Coupling Attached Type

Setscrew Type: Units are bored with two setscrews placed at 90 degree, this low-cost type features the most conventional attachment. However, the point of screw may cause damage to the shaft and may be difficult to remove.

Clamp Type: This type is clamped on the shaft by tightening the socket head cap screws. Attachment and removal is easy, and with no shaft damage.

Keyway Type: This type, like the setscrew type, features the most conventional attachment and is used for transmitting high torque.

Locking Type: This type is a self-contained, frictional shaft-hub, locking device. Designed to be easily adjustable and release on a shaft. They can transmit high torque.

Danger

For safe operation, couplings and other parts must be secure and protected by covers.

Do not touch the product during operation. Disconnect power to the connection while servicing or installation. Use a torque wrench to secure setscrews and cap screws. Do not exceed the rated maximum torque, misalignment factor or rpm designed for the unit.

Read More About Encoder Flex Coupling | Read More About Steel Jaw Coupling | Read More About Jaw Coupling